Perhaps the most important tools for building gliders are sanding blocks, store bought ones simply aren’t appropriate for what we do. Make at least two of your own using straight flat wood, balsa will do. They should be approximately 1 x 2 x 7 and 1 x 1.5 x 5. Glue 100 grit sandpaper on one side and 150 grit on the other. For final smoothing use a folded piece of 320 grit.

Always strive to make good joints. Gliders sometimes get a lot of abuse and good joints will help keep it together.

Use instant glue. A good technique is to glue pieces together with just one drop and then check for proper alignment. Slight adjustments can be made before adding more glue. Use wax paper to keep the model from sticking to the work table.

Pay attention to the airfoil shapes and thickness on the plan. Getting a surface too thin can lead to warps and breakage, leave it too thick and the model will get heavy in a hurry.

Building surface: Use something smooth and flat – a piece of shelf, glass, marble, etc. In a pinch laying layers of newspaper on a work bench can work.

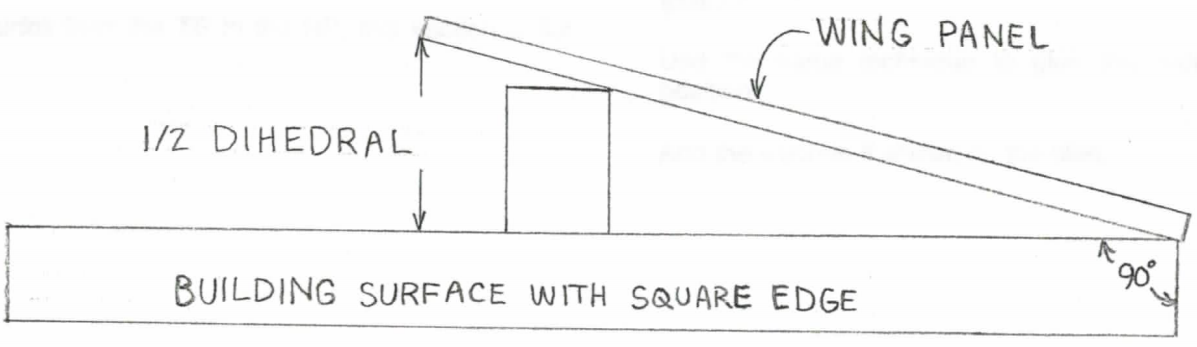

Dihedral angles: Prop the wing panel up to the correct angle and use the 150 grit side of the large block to sand the joint edge flush with the 90 degree edge of the building surface. (see drawing).

TEP BY STEP

WING

Shape the wing to the outline on the plan, attach the hardwood leading edge if required.

Sand the thickness taper into the top of the wing.

Mark the highpoint (HP) line on to the top of the wing. Use a broad tip marker to make lines from the trailing edge (TE) to the leading edge (LE) at 1/2" intervals over the entire top of the wing. As you sand the airfoil the marks will disappear and you will get a better impression of how the work is progressing.

Shape the airfoil from the LE to the HP, don’t sand off the HP line yet, the smaller sanding block will give better control for this. Pause frequently to check your work.

Shape the airfoil from the TE to the HP, this section is flat (no curve).

Do the final shaping of the LE, careful, this is important for top performance. Sand everything smooth with 320 grit.

Run some instant glue along the LE, a short section at a time, wiping it quickly with a paper towel. This will greatly increase ding resistance.

Cut the wing apart at the dihedral joints, it is best to use a very fine hobby razor saw but a sharp hobby knife will do. Carefully sand and glue the dihedral joint.

STABILIZER AND RUDDER

Follow the same general procedure used on the wing. My kit pieces are about the right thickness when you get them, if there is a thick edge it should be the LE, you don’t need to do much more than rounding and smoothing.

FUSELAGE

All balsa fuselages are straight side to side when they leave the "Stuff" factory and have 1/2 to 1 degree of positive incidence, the top edge is marked. If yours has warped it can usually be straightened by careful bending in the opposite direction.

ASSEMBLY

Note: Left and Right are oriented looking from the back to the front of the model. These instructions are written for a right hand launch - right bank on launch with a left glide circle. For left hand launch reverse the stabilizer tilt, rudder offset, and wash-in.

On wings that have a center dihedral joint sand the bottom flat so that it sits square on top of the fuselage. Glue the wing to the fuselage.

Carefully align the stabilizer and tack glue it in place. A good technique is to use UHU brand of office glue stick, just a bit or the instant glue won’t bond well, it will hold the stab in place but allow easy repositioning. When it measures just right secure it with instant glue. Don't use much glue stick or the instant glue won't bond well.

Use the same technique to glue the rudder in position.

Add the wash-in if shown on the plan.

FINISH

Adding some finish will reduce drag and, with this method, prevent unwanted warps. Use MinWax Helmsman Spar Urethane found at the hardware store. With a 1/8 x ¾ x 6 stick dip some finish onto the glider and spread it as far as possible. Now smear it around and wipe it off, gently, with a folded paper towel (wear disposable gloves). Do this gently, you are NOT trying to rub it all off but you want to sop up most of it that you can. The surface should be damp, not wet, with finish.

One coat if you are in a hurry, two coats if you expect it might get water on it. A light sanding with 400 grit will get it smooth enough.

ADJUSTING/TRIMMING

Catapults go through a ferocious speed change between launch and glide. Various aspects of the glider have more, or less, effect depending on the speed. At high speed rudder offset has a very large effect, at low speed stab tilt and tip weight have their greatest effect. Warps are also speed sensitive. VERY small warps (1/64") can have a large effect. Most trim should be built in, fine tuning can be done at the field by careful bending, or screw adjusting, or weight changes with clay.

FLYING

Add weight to the nose until the glider balances about 1/8” in front of the CG shown on the plan. Adjust the stabilizer incidence, TE up or down, until a gentle level toss into the wind produces a smooth glide. With a harder straight ahead toss the model should gently rise and go into a wide turn – not dive, or stall and dive, to the ground. It can stall a little at this point but should not then dive nearly straight in. This forward CG, and the incidence to go with it, will give the model a better chance on not crashing as you learn to launch. As you become confident in your launch gradually reduce the incidence and the nose weight (don’t get carried away or it will dive in!).

LAUNCHING

The optimum launch angles for most catapults are 60 to 80 degrees nose up and 20 to 45 degrees right bank (see plan for the Scout angles). With the thumb and forefinger pointed up and the other three fingertips curled into your palm, reach back and grasp the glider with the tip of your thumb and forefinger. Hold the launcher in front of you, pull HARD, and let go with confidence.

INCIDENCE

Incidence is the angular difference between the wing and the stabilizer. The higher the TE of the Stab is compared to its LE, or the higher the LE of the wing is compared to its TE, the more loopy the model will be at high speed. Loopiness robs altitude but you need some of this for a good stabile glide.

As you progress you will want to get all of the altitude you can so you will need to fine tune the adjustments. At the top of the launch the glider should almost stop before turning/plopping into the glide. At this point it should be just past vertical, it should have launched in a partial loop so that it comes to the point of transition just beyond straight up, very high but sort of barely behind you. If 90 degrees is straight up then it should come almost to a stop and transition to glide at about 100 deg. If the model is zooming past the 100 degrees before transitioning, looping too much, then decrease the incidence (stab TE down) a very small amount. Do the opposite if the model comes to a stop going sort of straight up and then dives to the ground. An adjustment would be bending an area the size of the end of your finger about 1/64" or 1/4 turn of the screw.

RUDDER TURN

Rudder turn is used to roll the model left as it climbs to the right during launch. Make tiny adjustments to the rudder (as above). The rudder is extremely sensitive at high speed and to much offset can cause the model to spiral in to the left. Always bend the rudder, if necessary, near the fuselage – bending it out at the tip can increase sensitivity. Once you have the rudder correct for launch any glide turn changes must be done with other adjustments. A 50 to 100 foot diameter circle is good.

Hopefully this will get you started. ENJOY!